14 Sep MedCuore: A Covid Startup aims Indoor air quality

MedCuore, an indoor air quality monitoring & solution provider, provide affordable air purification solution through Made in India components.

Covid pandemic saw many entrepreneurs come forward to help the fight. This is also the story of MedCuore, which started its journey at the peak of the first wave in June 2020, helping provide rental oxygen concentrators, BIPAP and CPAP machines to needy patients. They served more than 2,750 COVID patients and helped save 2700+ lives.

But for MedCuore founder Paul Pradeep J, it also served as a path to understanding the need for tackling indoor air pollution and this startup pivoted even as it still continues to serve the patients. MedCuore, a indoor air quality monitoring & solution provider, is one the startup currently a part of AIC-IIITH’s EPAM Social Impact Innovation program (ESIIP), an acceleration program funded by EPAM Systems India.

In the fight against Covid, Paul realized virus transmission is aggravated because of indoor air pollution. Full appreciation of this came as they measured the air quality at homes of various patients they were serving. As he dived deeper into the problem, the full magnitude of the problem became clear. Indoor pollution is more dangerous than outdoor pollution as the concentration indoor is higher and we spend the majority of our time indoors.. And as per WHO, from the year 2021, the rate of respiratory problems throughout the world has increased 14.7%. Paul discovered that every year in India alone, two lakh children between ages 1-13 age die due to air pollution. Paul understood improvement of indoor air quality is essential if we want to improve our long term respiratory health.

Available air purifiers were mostly expensive foreign made models which covered a limited area. There was a need and space in the market for better air purifiers. Paul, who has experience working in Taiwan and with J&J, was pursuing a PHD in Italy in the area of Biomaterial and Biomechanics in 2020 when he came back to India and stayed back as lockdown began. Paul saw that at that time Chennai did not have adequate numbers of biomedical engineers and hence with friends started to work during COVID help provide oxygen concentrators.

He then used this knowledge to devise a solution to the air purifier problem. The goal was to create a solution which was low cost, covered a large area and was made in India. It also had to be environmentally friendly.

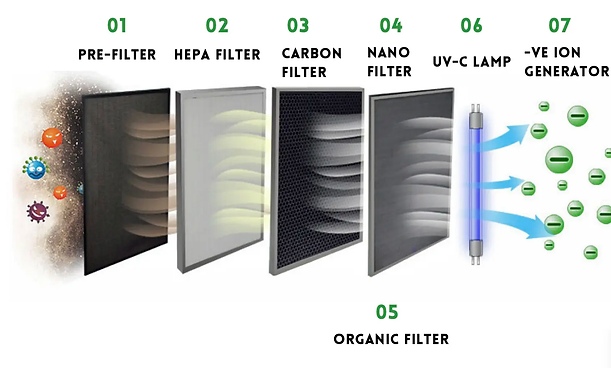

Key innovation that Paul came up with was to combine traditional HEPA filters with nano organic components inside their air purification system. This organic filter directly decomposes pollution that is present in the air. These organic filters are very easy to make and the cost of manufacturing one Nano organic air filter is only INR 2-3. This in turn increased the life of HEPA filters. Traditional air purifiers only use HEPA filters which need to be replaced every 4-6 months. Thus with these organic filters MedCuore is able to achieve cost reduction. MedCuore has already applied for a patent for these filters.

Source: https://www.medcuore.com/airpurifier

Another USP for MedCuore is that the most competent are manufactured in India by SMBs. For example activated carbon is from a local SMB from Kerala and HEPA filter is from a local SMB from Mumbai etc. thereby establishing a local ecosystem. Otherwise these SMBs were exporting components to other countries and from there, the finished filters were imported into India. Instead MedCuore manufactured the filter itself by assembling components from these SMBs directly.

MedCuore competitive edge comes down to two factors – Cost and efficiency. Their machine can cover a larger area, approx. 1000 square feet at a low cost of INR 12,500. Other filters on Amazon, Flipkart etc., in the price range of INR 10,000 -INR 20,000 can cover a maximum of 700 square feet. MedCuore 7 Stage filtration modules which address 27 different physical, chemical and biological pollutants (particulate matter, CO2, CO, excess humidity etc.). The filter has a life of 1 year compared to approx. 6 months for existing ones. Plus the cost of filtration replacement is ⅓ of existing models leading to additional savings (cost of INR 1250 for MedCuore compared to INR 2000-3000 for other machines). The monthly cost of running a machine is INR 40 compared to INR 120-150.

After one year of bootstrapping, MedCuore was able to secure outside support. This includes grants like NDHI for Covid (INR 17.5 Lakhs); NIDHI PRYAS (INR 9.5 Lakhs); IVP – (INR 4.5 Lakhs). They have also secured support for IIT Madras on INR 20 Lakhs to develop and implement their new product – air quality monitors in phases. IIT Madras also helped them with product delivery and marketing. They also won the IIC MIC social Innovation award.

In December 2022, Paul along with his co-founder Prem Kumar Kannappan, whom Paul met via LinkedIn, joined ESIIP run by AIC-IIITH with EPAM India. The program grant helped them plan and execute pilot studies quickly by allowing them to manufacture 50 units of prototype and purchase a sensor for these – IOT based Air Quality monitors (which can cover large areas, monitor air quality in real time and detect physical and chemical pollutants). Paul says they appreciate the AIC-IITHs process as it includes not grant and just mentorship but also handholding, monthly bootcamps which they like as it shows the care AIC puts in their cohorts. Moreover, association with AIC-IIITH helped them indirectly establish connections with two companies (Gamlaa and Cumins) who have become their customers. Paul thinks all incubators should follow processes like AIC-IIITH.

A major challenge faced by MedCuore and others in the sector is the lack of a proper system for testing and certification of air purification. Available infrastructure is not startups friendly and expensive.

MedCuore has also gained traction in the market, the real validation for any startup. Their first 50 customers came from their Oxygen Concentrator network esp. deal and distributors from Chennai, Delhi, Bangalore and Mumbai helped get them traction. They sold the first 500 purifiers in 1 month. With the next version of their air purifier, till now they have served eight corporate companies and 400 plus clients.

Paul says their major achievement till date has been cracking complete manufacturing in India – prototype to product. Vision for MedCuore is to create a low cost passive purification and passive air quality monitoring system and their long term goal is to cover around 15 lakh square feet in next three years with their air purification system. Having already saved 2500+ lives they are also aiming to create employment in tier 2 and 3 cities via low cost manufacturing of their product. Paul says running a startup has given him the confidence to develop something for our society and he has developed an attitude of not giving up.

Edited By Ravi Sarkunan.